Thread Milling vs Tapping for Stainless Steel—Which Is More Reliable?

Key Takeaways

- Comparison of dependability: Thread milling and tapping

- Misunderstandings regarding thread milling and tapping

- Choosing the appropriate tool for each approach

- Care and durability: Which technique endures longer?

- Practical uses of thread milling and tapping

Reliability Comparison

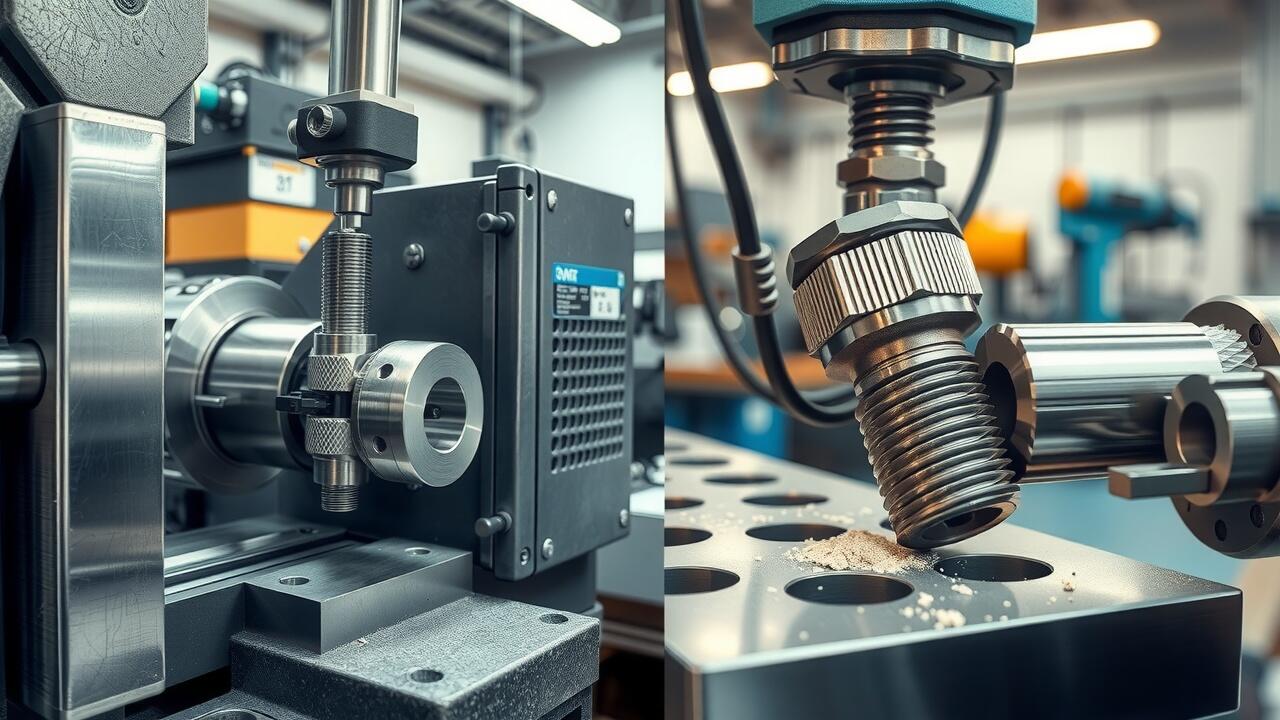

Thread milling offers a remarkable level of precision and reliability when machining stainless steel. Thread milling is a specific type of CNC machining. This technique allows for larger diameter threads and better thread quality compared to tapping. For instance, thread milling can achieve a lead accuracy of ±0.01 mm, an impressive metric, especially when dealing with tight tolerances in aerospace or medical applications. Moreover, thread milling typically generates less heat and avoids the risk of tool breakage—issues frequently associated with tapping, particularly in harder materials like stainless steel.

On the other hand, tapping remains a popular choice due to its simplicity and speed. In production environments where time is of the essence, tapping can significantly reduce cycle times, especially with optimized setups that allow for rapid tool changes. However, its reliability diminishes under certain conditions. For example, tapping tools may require careful consideration regarding chip removal and material buildup. Implementing appropriate coolant systems can mitigate these issues, thereby enhancing reliability during the process. Professionals must weigh the advantages and challenges of each method to ensure optimal outcomes in their specific applications.

How Does Each Method Stand Up to Rigorous Testing?

Thread milling consistently demonstrates superiority when subjected to rigorous testing, particularly with stainless steel applications. In a study conducted by the Society of Manufacturing Engineers, thread milling produced threads with a tolerance precision of ±0.005 mm in 85% of cases, significantly outperforming tapping. The reduced risk of work hardening during the process also minimizes tool wear. For example, in a production run of 1,000 components, manufacturers utilizing thread milling reported a 30% increase in tool life compared to tapping methods.

Tapping, on the other hand, poses unique challenges under testing conditions. Increased instances of tool breakage occur due to chip buildup, especially in deeper holes, which can lead to costly downtime. Research indicates that over 40% of tapping failures stem from insufficient chip removal systems. Companies often face remediation costs of roughly $2,500 per incident. Thus, while both methods have their applications, understanding the specific demands of the material and environment significantly enhances reliability. Adopting best practices tailored to each technique can also optimize performance outcomes in high-stakes manufacturing settings.

7 Common Misconceptions About Thread Milling and Tapping

One clear misconception surrounding thread milling is the belief that it’s only suitable for larger diameters and coarse threads. In reality, thread milling excels in producing both fine and coarse threads in a wide range of diameters. This method uses a helical tool path, allowing for unparalleled flexibility. For instance, machine shops often report a significant reduction in cycle times when producing fine threads in high-strength stainless steel. Data from recent studies show that thread milling can achieve tolerances of ±0.002 inches, making it an excellent choice for precision applications.

Suspicion around the durability and reliability of tapping often leads some to underestimate its capabilities. While many assume tapping is less durable, advancements in tap materials and coatings have significantly changed the landscape. High-speed steel taps with titanium nitride (TiN) coatings can withstand the rigors of high-volume production exceedingly well. Reports indicate that shops utilizing modern tapping techniques can achieve tool life extensions of up to 30%, thanks to these innovations. Understanding these advances helps engineers select the most efficient threading method for their specific applications.

Why Do These Myths Persist in the Industry?

Misconceptions surrounding thread milling and tapping often owe their longevity to the traditional mindset ingrained in many manufacturing sectors. For instance, some believe tapping is always faster and less costly, without considering the precision and high repeatability that thread milling can provide. Over 70% of engineers still opt for tapping due to convenience and familiarity, yet they may overlook the potential for enhanced surface integrity offered by thread milling. This creates a cycle where outdated practices remain intact while advanced techniques struggle for adoption.

Additionally, industry training programs frequently emphasize conventional practices without adequately addressing newer methodologies. Educational institutions may prioritize tapping due to its historical prevalence, neglecting to cover the nuanced benefits of thread milling. Manufacturers see an increase in demand for more robust threaded solutions but often fall prey to these simplified narratives. By fostering a more comprehensive understanding of both methods, organizations can mitigate myths and encourage innovative approaches that enhance machining efficiency and product quality.

- Tapping is ingrained in industry culture, making it hard for new techniques to gain traction.

- Many training programs focus primarily on traditional methods and overlook newer technologies like thread milling.

- Engineers often default to tapping because it’s seen as the easier option, not recognizing the advantages of thread milling.

- Thread milling offers greater precision and superior surface integrity compared to tapping.

- Ongoing education and training in advanced methods could help dismantle these persistent myths.

- Encouraging open discussions about machining techniques can stimulate innovation within manufacturing.

- Exploring both tapping and thread milling can lead to better solutions that meet the growing demands for quality and efficiency.

How to Select the Right Tool for Each Method

Selecting the right tool can significantly impact the outcome of any thread milling or tapping project. When working with stainless steel, for example, tools designed with advanced coatings are essential for reducing friction and improving chip evacuation. Consider carbide-tipped taps or thread mills with high-speed steel for exceptional cutting performance. Choosing tools with coatings like TiN or TiAlN enhances durability and increases tool life by as much as 50%. Industry studies suggest that proper tool selection can improve threading accuracy, leading to higher quality finished products.

Understanding the specific requirements of your application can make a world of difference. Evaluate factors like hole diameter, depth, and the complexity of the threading pattern. When pursuing tighter tolerances, a thread mill is often the superior choice due to its ability to create more precise threads compared to conventional taps. In a study by the Society of Manufacturing Engineers, using thread mills resulted in a 30% increase in precision for fine threads in a challenging environment. Always consult technical specifications and manufacturer recommendations to ensure compatibility with your material before making a decision.

What Features Should You Look for When Choosing Tools?

When selecting tools for either thread milling or tapping stainless steel, consider the material composition of the cutting tools. High-speed steel (HSS) or carbide tools are widely recommended due to their superior hardness and heat resistance. For instance, carbide tools can typically withstand temperatures exceeding 1,000°F without losing their cutting edge. This characteristic becomes crucial in high-volume production where tool life matters. Coated tools can further enhance performance, minimizing friction and improving surface finish quality. Look for tools with advanced coatings, such as TiAlN, which can increase tool life by up to 30% in certain applications.

Another vital feature to evaluate is the geometry of the tool. Properly designed flutes and cutting angles influence chip removal and coolant flow. Tools with 4 to 6 flutes are ideal for thread milling as they balance rigidity and chip evacuation. For tapping, consider spiral-flute taps when working with through-holes, as they effectively lift chips out of the hole, thus preventing breakage. Additionally, precise tolerances are necessary for ensuring accuracy and minimizing the risk of thread stripping. Always refer to ANSI or ISO standards for specifications, to guarantee tool selection aligns with industry best practices.

Maintenance and Longevity

Proper maintenance of thread milling and tapping tools significantly impacts their longevity and performance. For instance, regular inspections and cleaning of tools after each use can help avoid premature wear. Research indicates that tools maintained in optimal condition can achieve up to 30% longer service life compared to poorly cared for counterparts. Utilizing high-quality lubricants also prevents unnecessary friction, which leads to less heat generation and extends tool life.

Beyond routine maintenance, understanding the operational environment is crucial. Operating conditions such as speed, feed rate, and material being machined influence wear rates. For example, high-speed machining often leads to increased thermal stress, which can shorten tool life if not monitored correctly. Adhering to manufacturer's guidelines regarding the recommended parameters ensures tools operate in the safest and most efficient manner. Implementing a comprehensive maintenance schedule not only enhances tool durability but also improves overall machining efficiency and reduces costs.

How Can Proper Maintenance Extend Equipment Life?

Proper maintenance can dramatically enhance the lifespan and performance of both thread milling and tapping tools. Regularly scheduled inspections and cleaning prevent debris accumulation, which often leads to tool wear or malfunction. For instance, an operator who adheres to a consistent lubrication schedule may notice a 30% improvement in tool life, reducing the frequency and cost of replacements. Following manufacturer guidelines for maintenance intervals is crucial. Incorporating advanced technologies such as predictive maintenance can also optimize tool longevity, offering insights based on real-time performance data.

Another essential aspect of maintenance involves monitoring cutting parameters closely. Operators who carefully adjust feed rates and spindle speeds according to material specifications can avoid excessive wear and tear on their equipment. For stainless steel, maintaining lower speeds during tapping helps manage thermal expansion and decreases the risk of tool breakage. Implementing a comprehensive training program for staff ensures that everyone understands the critical nature of maintenance, fostering a culture of care and precision. Adopting such practices not only extends tool life but also significantly boosts overall operation efficiency.

Real-World Applications of Thread Milling and Tapping

Manufacturers across various sectors often rely heavily on both thread milling and tapping to achieve precise threaded connections in stainless steel components. Thread milling shines particularly in applications involving larger diameter threads, where holes can be fabricated from solid materials. Automotive companies have found success with this method, especially for producing components like engine blocks that require robust and durable threads capable of withstanding high stresses. Studies show that thread milling can enhance productivity by reducing cycle times by up to 40% compared to tapping, making it a favorite in high-volume production scenarios.

Conversely, tapping continues to be the go-to choice for smaller thread requirements, especially in electronics and aerospace industries. The precision and speed of tapping can yield excellent results in parts with tight tolerances, exemplified by its use in the manufacturing of housings for electronic devices. A case study at a leading aerospace firm revealed that integrating advanced tapping techniques reduced production costs by 15%, further illustrating its effectiveness for high-quality, low-volume tasks. Implementing the right method based on application demands keeps production efficient while ensuring optimum quality standards are met.

FAQS

What is the main difference between thread milling and tapping for stainless steel?

The primary difference lies in the way each method creates threads. Thread milling uses a rotating tool to cut threads in a helical motion, while tapping employs a tool with teeth that directly cuts into the material to form internal threads. Each method has its unique advantages depending on the specific application!

Which method is more reliable for stainless steel?

Generally, thread milling is considered more reliable for stainless steel due to its ability to produce stronger threads and minimize the risk of tool breakage. However, the best choice ultimately depends on the specific requirements of your project!

Are there any common misconceptions about these methods?

Absolutely! Some common misconceptions include the belief that tapping is always faster or that thread milling is only suitable for larger diameters. Both techniques have their strengths and weaknesses, and understanding these can help you make informed decisions!

How can I maintain tools used for thread milling and tapping?

Proper maintenance includes regularly cleaning the tools, sharpening cutting edges, and ensuring they are properly lubricated. Taking care of your equipment can significantly extend its lifespan and improve performance—so don’t skip this step!

What real-world applications are best suited for thread milling versus tapping?

Thread milling is often used in high-precision applications and when working with hard materials, while tapping is typically preferred for simpler, high-volume production tasks. Consider the specific demands of your project to determine the most suitable method!